- IMPOSITION WIZARD AUTOMATION PDF

- IMPOSITION WIZARD AUTOMATION INSTALL

- IMPOSITION WIZARD AUTOMATION PROFESSIONAL

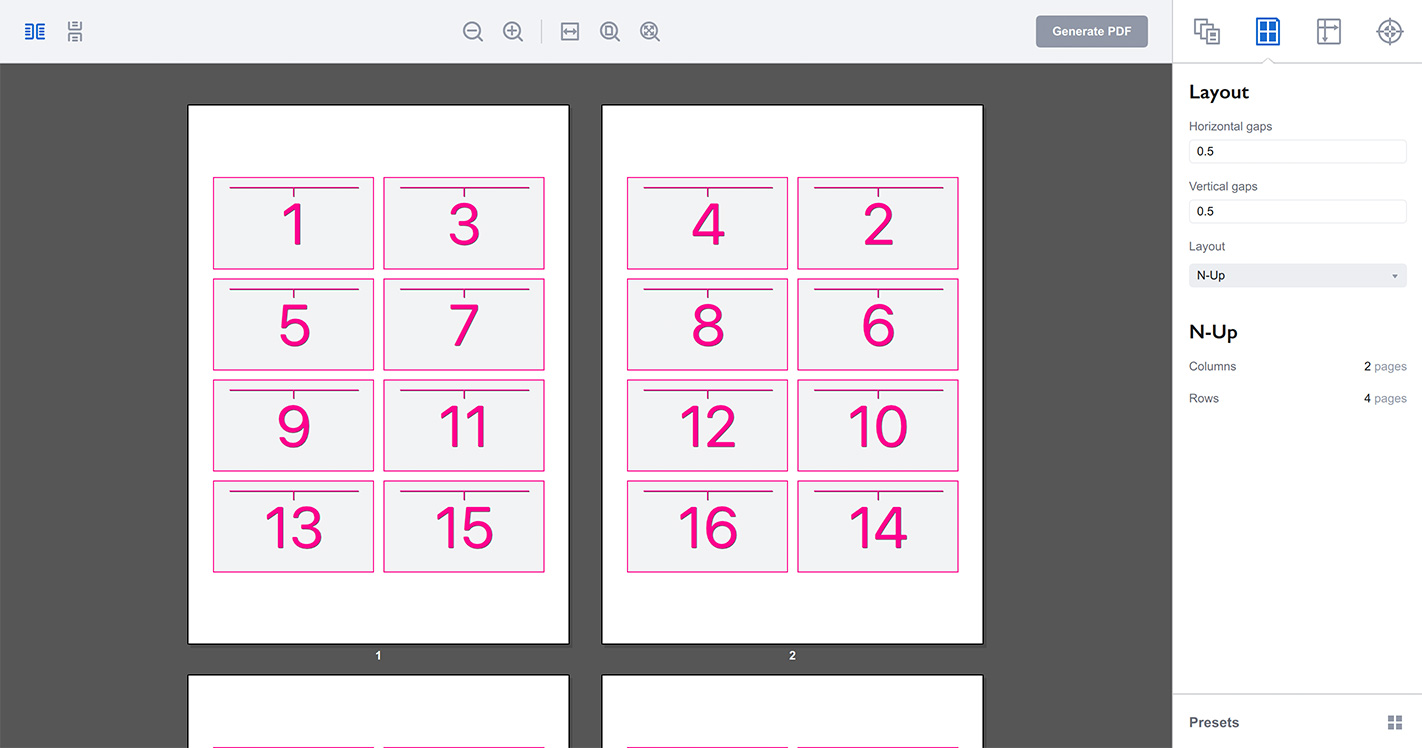

Take anything you can do in inpO2 Wizard and make it as simple as "drag and drop". See your run length based on your quantities, paper waste and make adjustments to get just the right layout for your ganging needs. Import your files, define your press sheet, quantities, and finishing methods then inpO2 Optimization does the rest. Optimization makes ganging multiple jobs on a single sheet easy and flexible.

IMPOSITION WIZARD AUTOMATION PROFESSIONAL

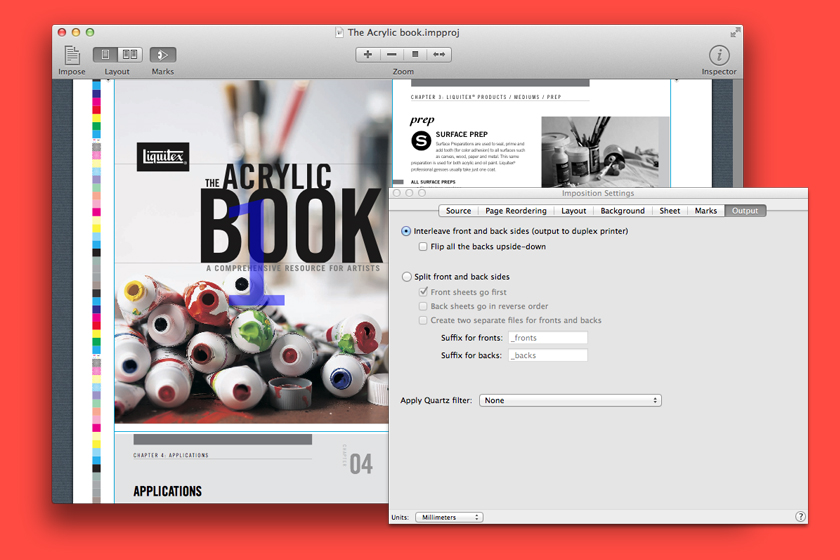

In addition, other professional features such as page level controls, mark sets, ink merging and more! Network licenses are also available for customers who need multiple seats. inpO2 Pro+ adds template based assembly for offset and web press printing, along with our inpO2 planner for interactive imposition planning. (Wizard + Layout Editor + Assembly Planner + Automation + Optimization + JDF)

See below for more information on the Wizard and Layout Editor. inpO2+ is perfect for basic offset and digital printing applications. The easy to use and cost effective starting point for the rest of the inpO2 product line. (Wizard + Layout Editor + Automation + Optimization + JDF) As a modular imposition solution, you can pick the right features to meet your production needs and budget.

IMPOSITION WIZARD AUTOMATION PDF

InpO2 is a powerful, modular PDF imposition software, built right into the familiar environment of Acrobat DC. New automation solutions have aerospace production humming, with automated-guided vehicles (AGVs) and mobile robotics solutions helping aerospace and defense builders meet demanding production schedules for delivery of new commercial and military aircraft.Flexible Imposition for Digital, Offset and Web Printers Picking Up the Pace in Aerospace Production this week demonstrated a new factory automatic guided vehicle (AGV) capable of changing routes on the fly. But if you’re struggling with high-speed machining, need better surface finishes or higher accuracy, have training and retention problems, or want a better handle on your production efficiency, the answer just might be the latest iterations of those three little letters. And much of the time it’s probably OK to view your “computer numerical control” as a black box doing magic. It’s the machine tool acronym you never bother to put into words: CNC. Modern CNCs Make Easy Work Out of Tough Stuff In addition to functioning as a classroom teaching and learning tool, DM enables companies to do training and testing before ramp-up and simulation during production.

IMPOSITION WIZARD AUTOMATION INSTALL

Using Blockly to make robots easier to install and operate without specialized training.įastems Launches Digital Manufacturing Solutions to Teach Automation to Students and Employeesįastems LLC has launched three new products to enable educational institutions and manufacturing enterprises to benefit from its advanced Digital Manufacturing (DM) solutions for factory automation. But what may be surprising is that the venerable, tried and true Swiss automatic CNC lathe coninues to evolve, adding bells and whistles where needed, or conversely stripping one-like a guide bushing-away to maximize its efficiency in machining parts complete.ĪBB Announces New Programing Wizard For Its Cobots Last year’s surge in medical machining and firearms manufacturing could well be joined or even eclipsed by this years’ reemergence of production for applications in the automotive, aerospace, electronics, and hydraulics industries, generating increased interest in Swiss-style machining. The basic elements are a servomotor a device to convert rotary motion into linear motion a suite of sensors to provide the required feedback a controller to convert feedback data into command signals and enabling software. Servomechanisms are at the heart of 21st century automation. Regional Experts: Training, Flexibility Key to RecoveryĪround the U.S., the major manufacturing regions are taking stock of the fallout from the pandemic and how they can navigate out of the lockdowns in 2020 to thrive once again. Worker training will be key to implementing Industry 4.0 in manufacturing, speakers at a presentation said today. Industry 4.0 Presents Training Challenges Tooling U-SME proves the most helpful training to Iowa’s Rosenboom because employees learn things online that are immediately applicable.

0 kommentar(er)

0 kommentar(er)